Interior cleaning of IBC totes

The interior of a container is cleaned using a rotating cleaning head. The cleaning head is inserted into the IBC or stainless steel container manually or automatically. There are many different types of cleaning heads available:

spray angle (180°-360°)

drive (electric, pneumatic, water-driven)

operating pressure (from 5 to 500 bar)

water consumption (15-200 litres per minute)

deployment area/industry type (food, pharma, chemicals, etc.)

Exterior cleaning

IBCs or stainless steel containers can be cleaned on the outside both manually and automatically, using different operating pressures (5 to 500 bar)

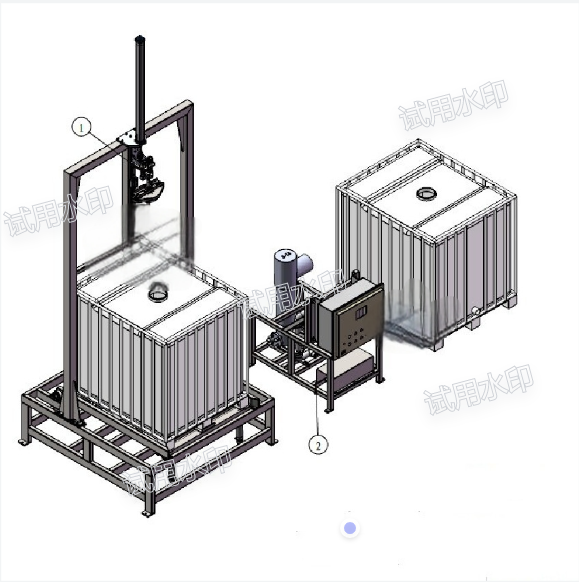

- automatic IBC tote washer equipment design feature:

1. Compact structure and high degree of automation, which can replace manual cleaning operations;

2. Saving manpower and material resources, greatly improving production efficiency and greatly reducing labor intensity;

3. High efficient cleaning of IBC totes, average of 2-4 minutes of cleaning cycle time;

4. The investment is quick and effective, solves the problem of recruiting cleaning workers, and greatly improves the working environment;

5. Pressure range from 5-500 bar to solve the cleaning problems of various working conditions;

6. This IBC cleaning system adopts precise 360° 3D IBC tote roaty jet cleaning head, which has high impact force and low liquid consumption. 360 coverage, 100% thorough clean

IBC tote tank wash equipment product Photo: