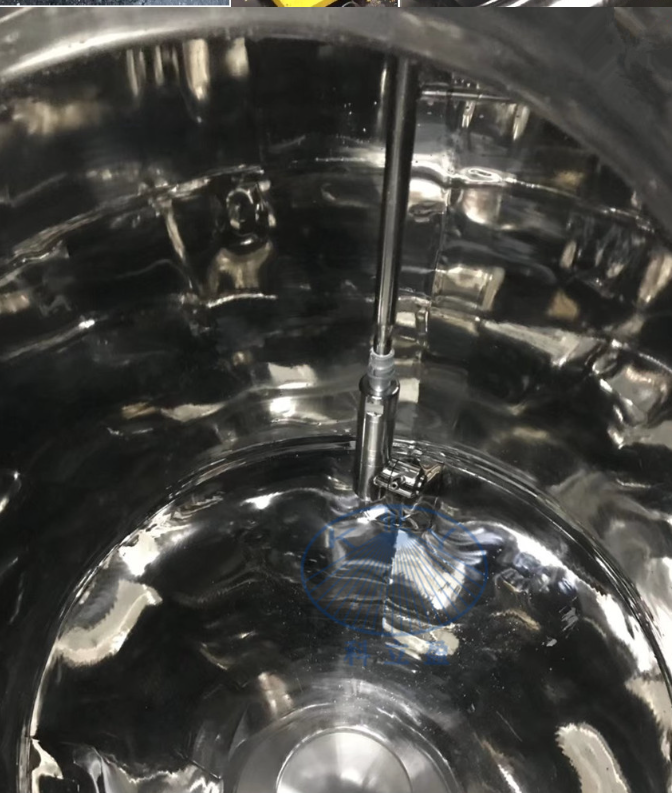

High impact 3D rotary tank washer

Model number:STD 20 3D rotary jet head

Impeller is driven by cleaning fluid and drives internal reduction mechanism. Gear mechanism operates according to set track to realize the revolution and the rotation, thereby achieving 360° thorough cleaning.

Programmed rotation machines:The cleaning fluid drives via the turbine an internal gear reducer that keeps the sprayer turning in two planes.In the course of spraying cycle, the jets sweep the entire inside surface of the tank according to the preprogrammed, model-specific pattern.This takes a certain amount of time, but these models generate the highest jet pressures (= force of impact) and are therefore ideal for very large tanks and the toughest of cleaning tasks.

The standard machine configuration uses two or four nozzles to blast the tank walls and rinse all surfaces. In operation, the unit has to run for the cycle time between on type 8 and 12 min depending on type and pressure. This ensures full cleaning. For extremely difficult applications the cleaning time might have to be extend.

Features & Benefits:

● Optimized structural design results in a water jet that produces greater impact

● Excellent sealing design, less than 3% leakage, thus saves cleaning fluid

● Independent gearbox design protects gear from damage and can work in poor water quality

● Adopt high hardness and wear resistant materials, long service life

● The rotating shaft and other parts are made of tungsten carbide, which has a longer service life

T

Cleaing Effection ( Before & After )

Application:

STD DG20 series rotary tank washer is suitable for three-dimensional cleaning of medium and large tanks, spray dryer, fracturing mud tanks, fermentation tanks, cabin and storage tanks, such as oil tank cleaning stations, beer, pharmaceuticals, marine, chemical, industrial fermentation industry and occasions requiring high-impact cleaning.